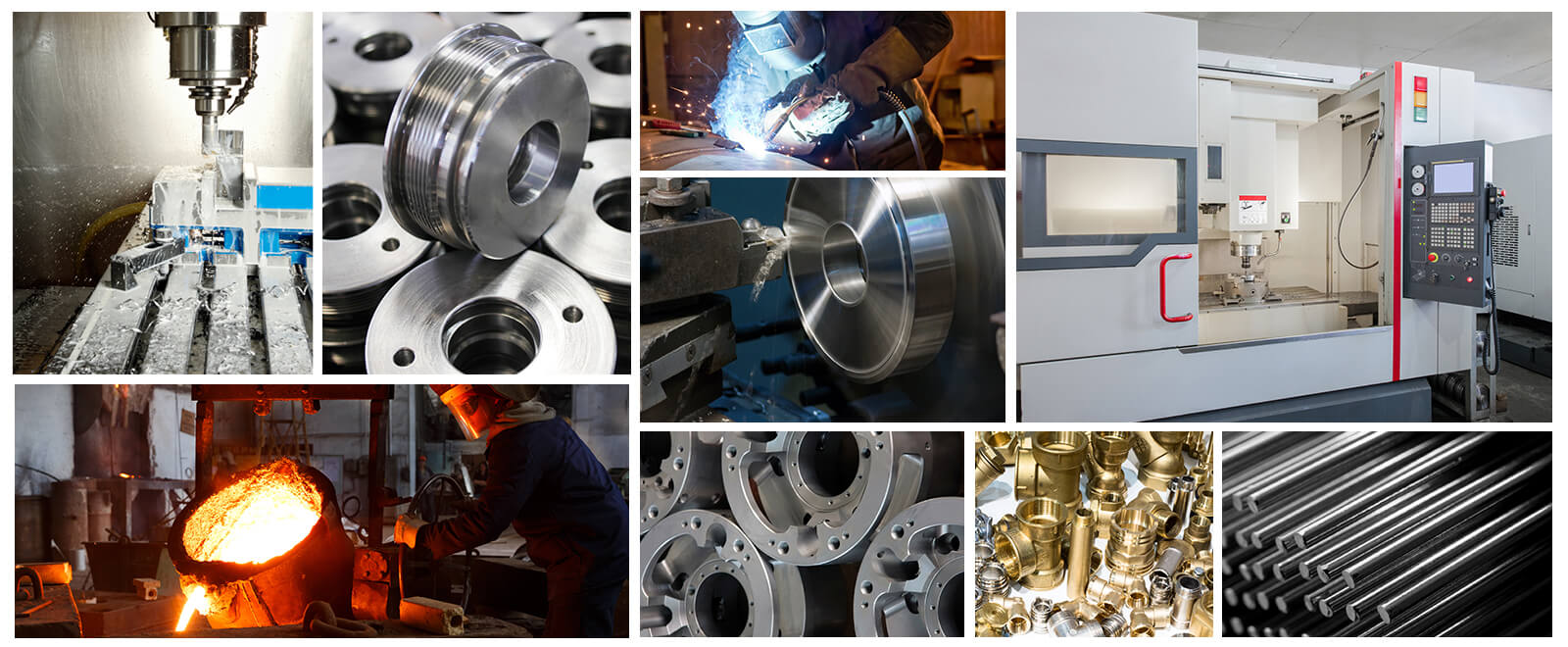

METAL MANUFACTURING

STAINLESS STEEL, STEEL, NICKEL, BRASS, ZINC, ALUMINUM, COPPER

Here are some of the most common metal manufacturing methods we work with:

Machining

Process such as cutting, milling, turning, drilling, grinding, threading, and/or shaping of a piece of metal or other material performed by machine tools such as lathes, milling machines, power saws, and presses.

CNC Machining

Control of a machine tool through programming to ensure precision and accuracy.

Casting

Manufacturing method in which a molten metal is injected or poured into a mold to form an object of the desired shape. Some most common types of castings include die-casting, sand casting, investment casting, and precision casting.

Forging

Manufacturing process in which a piece of cold or hot metal is formed into the desired shape by hammering, pressing, rolling, squeezing, or other such operations in one or more forging equipment.

Stamping

Metal forming method in which a sheet is shaped by bending, folding, pressing, stretching, and/or twisting, usually with pressing machinery.

Extrusion

Manufacturing process in which a softened blank metal material is forced through a shaped metal piece or die to produce a continuous ribbon of the formed product.

Welding

When you join together pieces of metal by heating and melting them together, normally a filler material is added to the joint to add additional strength and adherence to the base metal.